Conductive Tapes

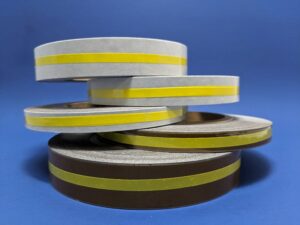

More flexibility, higher conductivity, and easier installation

Schlegel Electronics Materials’ (SEM) expanded line of Conductive Tapes meets the customer needs for flexibility, higher conductivity, and easier installation. They are vailable with conductive and non-conductive adhesives and in a wide range of widths.

Typical applications include cable Shielding terminations and joining metal panels together at the seams of an enclosure. Foil tapes are a cost-effective shielding solution for a wide range of uses. They can be particularly useful during the development and test phases of projects to be used as “fixes” for EMI problems.

SEM’s masked conductive tapes are also available and can be used as a gasket substrate on painted or stove enameled enclosures.

Also available are special purpose adhesive tapes to include:

- Pressure sensitive adhesive die-cuts

- High-tack adhesive die-cuts

- Low residueadhesive die-cuts

- Silicone adhesive die-cuts

- Insulation adhesive die-cuts

- Heat resistive adhesive die-cuts

SEM’s Conductive Tapes feature superior shear strength, 7.6 kPa (72+ hours @ 1.1 psi) in accordance to (PSTC #7) ASTM D 3654, and peel strength, 10.2 N/2.5 cm. (36.07 oz/inch width) in accordance to PSTC #1) ASTM D 3330, when compared to other EMI shielding tapes. This is made possible by a unique, cross-linking acrylic based, conductive Pressure Sensitive Adhesive (PSA) that also allows the tapes to be designed into higher temperature applications. The PSA is fire-rated to UL 510, and excessive pressure is not required for application to the end unit. There is now an easy-to-apply tape to fit most every EMI shielding design need.

Products

Schlegel Electronic Materials (SEM) offer the Black Conductive NiCu Fabric Tape which is similar to CFT(II) but blackened for the cosmetic purposes. The blackened conductive fabric was in rip-stop pattern with surface resistivity lower than 0.08 ohm/sq. The average shielding effectiveness over 95.6 dB in the frequency ranges from 20 MHz to 10 GHz. It provides the alternative to customer who prefer the black color conductive tape for the appearance design.

Specifications

Fabric: Nickel-Copper plated polyester ripstop fabric.

Adhesive: High-tack, conductive adhesive system.

Surface Resistivity: <= 0.08Ω/sq.

Resistivity through adhesive: <=20 milliohms/square inch.

Low Temperature Application: -40℉ (-40℃).

Abrasion Resistance: No change is surface resistivity and no fabric degradation after more than 1,000 wear cycles. Test method: ASTM D3884.

Shrinkage: <4% @ 180℃(356ºF) temperature.

Peel Strength: 50 oz. Per inch minimum initial. Test Method: ASTM D3330.

Shielding Effectiveness: 95.76dB Test method: Mil DTL 83528C.

Sizes

Tape Width | Tape Length | Part Number |

|---|---|---|

0.315″ (8.0 mm) | 36 yard (33m) rolls | 5921-0031-0 |

0.500″ (12.7 mm) | 36 yard (33m) rolls | 5921-0050-6 |

0.788″ (20.0 mm) | 36 yard (33m) rolls | 5921-0079-2 |

1.000″ (25.4 mm) | 36 yard (33m) rolls | 5921-0100-3 |

1.118″ (30.0 mm) | 36 yard (33m) rolls | 5921-0118-8 |

1.157″ (40.0 mm) | 36 yard (33m) rolls | 5921-0157-2 |

2.000″ (50.8 mm) | 36 yard (33m) rolls | 5921-0200-5 |

Higher conductivity without the sharp edges

Conductive Silver Fabric Tape (CST) offers superb conductivity and ease of installation for a wide range of applications. The smooth, soft-edged tape will not crack after repeated flexing, or cause injuries. Schlegel Electronics Materials (SEM) CST achieves total coverage, even on irregular surfaces and experiences no significant shrinkage at temperatures up to 180ºC (356ºF).

A unique, conductive Pressure Sensitive Adhesive (PSA) allows the tapes to be designed into higher temperature applications. The PSA is fire rate to UL 510, and excessive pressure is not required for application to the end unit.

CST tape has an average shielding effectiveness of 70 dB in the range of 20 MHz to 10 GHz. CST’s protective C2 coating lowers the cathodic potential of the silver to make it galvanically compatible with a variety of EMI gaskets and cabinet surfaces.

A superior alternative to sharp, non-conforming foil tapes, SEM’s lightweight Conductive Silver Tape is ideal for grounding and for sealing small apertures in frames. It achieves total coverage, and experiences no significant shrinkage at temperatures up to 180ºC (356ºF).

For assemblers, the CST’s soft fabric is safe and easy to work with, and it stays firmly in place with SEM’s strong, high-tack conductive adhesive.

The conductive fabric base also allows the tape to be custom-cut in virtually any unique shape with simple, inexpensive tooling.

Specifications

Fabric:Silver woven nylon ripstop fabric with C2 anti-corrosion coating.

Adhesive: High-tack, conductive adhesive system.

Surface Resistivity: <= 0.5Ω/sq.

Test Method: ASTM F390 modified.

Resistivity through adhesive: <=120 milliohms/square inch.

Low Temperature Application: -40℉ (-40℃)

Abrasion Resistance: No change is surface resistivity and no fabric degradation after more than 800 wear cycles. Test method: ASTM D3884.

Peel Strength (Test Method ASTM D3330):

45.80 oz per inch (1.62g per mm) @ 1 hour dwell initial.

47.47 oz per inch (1.67g per mm) @24 hour dwell initial.

Shielding Effectiveness: 95dB. Test method: Mil DTL 83528C.

Sizes

Tape Width | Tape Length | Part Number |

|---|---|---|

0.315” (8mm) | 18 yard (16.45m) roll | 5941-0031-0 |

0.500” (12.7mm) | 18 yard (16.45m) roll | 5941-0050-6 |

0.788” (20mm) | 18 yard (16.45m) roll | 5941-0079-8 |

1.000” (25.4mm) | 18 yard (16.45m) roll | 5941-0100-3 |

1.181” (30mm) | 18 yard (16.45m) roll | 5941-0118-2 |

2.000” (50.8mm) | 18 yard (16.45m) roll | 5941-0200-5 |

Schlegel Electronics Materials’ (SEM) CFT is made from the same woven copper nickel fabric as its CMP and has the same conductive and galvanic capabilities. The copper nickel fabric, along with SEM’s aggressive high temperature resistant conductive PSA, is designed specifically for applications that do not require a mask, i.e., cabinets that are not going to be painted or powder coated.

Specifications

Fabric: Woven copper nickel fabric.

Adhesive: High-tack, aggressive conductive adhesive system.

Surface Resistivity:<= 0.024Ω/sq.

Resistivity through adhesive: <=10 milliohms/square inch.

Low Temperature Application: -40℉ (-40℃)

Abrasion Resistance: No change in surface resistivity after more than 1,000 wear cycles. Test method: ASMT D3884.

Shrinkage: <4% @ 180℃(356ºF) temperature.

Peel Strength: 50 oz. Per inch minimum initial. Test Method: ASTM D3330.

Shielding Effectiveness: 97.4dB. Test method: Mil DTL 83528C.

Sizes

Tape Width | Tape Length | Part Number |

|---|---|---|

0.315” (8.0 mm) | 36 yard (33m) rolls | 5927-0031-0 |

0.500” (12.7 mm) | 36 yard (33m) rolls | 5927-0050-6 |

0.788” (20.0 mm) | 36 yard (33m) rolls | 5927-0079-2 |

1.000” (25.4 mm) | 36 yard (33m) rolls | 5927-0100-3 |

1.181” (30.0 mm) | 36 yard (33m) rolls | 5927-0118-8 |

1.575” (40.0 mm) | 36 yard (33m) rolls | 5927-0157-2 |

2.000” (50.8 mm) | 36 yard (33m) rolls | 5927-0200-5 |

Schlegel Electronic Materials (SEM) offers the Conductive SnCu Fabric Tape which is made of Tin copper plain weave woven fabric with high conductivity PSA. This provides the good galvanic compatibility for most common materials and higher corrosion resistance which target for outdoor application. The average shielding effectiveness of conductive SnCu fabric tape is over 95.3 dB in the frequency ranges from 20 MHz to 10 GHz and the surface resistivity is less than 0.02 ohm/sq.

Specifications

Fabric: Tin Copper plated nylon plain weave fabric.

Adhesive: High-tack, conductive adhesive system.

Surface Resistivity: <=0.02Ω/sq.

Resistivity through adhesive: <=40 milliohms/square inch.

Low Temperature Application: -40℉ (-40℃)

Abrasion Resistance: No change in surface resistivity and no fabric degradation after more than 1,000 wear cycles Test method: ASMT D3884.

Shrinkage: <4% @ 180℃(356ºF) temperature.

Peel Strength: 50 oz. Per inch minimum initial. Test Method: ASTM D3330.

Shielding Effectiveness: 95.3dB Test method: Mil DTL 83528C.

Sizes

Tape Width | Tape Length | Part Number |

|---|---|---|

0.315″ (8.0 mm) | 36 yard (33m) rolls | 5926-0031-0 |

0.500″ (12.7 mm) | 36 yard (33m) rolls | 5926-0050-6 |

0.788″ (20.0 mm) | 36 yard (33m) rolls | 5926-0079-2 |

1.000″ (25.4 mm) | 36 yard (33m) rolls | 5926-0100-3 |

1.118″ (30.0 mm) | 36 yard (33m) rolls | 5926-0118-8 |

1.157″ (40.0 mm) | 36 yard (33m) rolls | 5926-0157-2 |

2.000″ (50.8 mm) | 36 yard (33m) rolls | 5926-0200-5 |

Shield enclosures safely and efficiently

Schlegel Electronics Materials’ (SEM) Conductive Mask Peel (CMP) tape simplifies the manufacture of painted enclosures. CMP is constructed of impenetrable, heat-release mask, highly conductive copper nickel fabric and strong high-tack, conductive adhesive, which secures the tape to the metal for superior EMI shielding. The tape employs Press, Paint, and Peel application and provides total coverage.

The CMP tape’s volume resistance is in the range of 0.8 ? cm [average]. When CMP is used with SEM’s EMI shielding gaskets, a highly conductive pathway is obtained, and provides excellent galvanic capability between mating surfaces. Typical applications include large cabinets, factory automation equipment and data storage units.

Press, paint and Peel application is simple, safe, and secure. The operator removes the release liner from the back of the fabric tape and applies it to the prepared bare metal surface. No sharp edges exist that could lead to injuries. The 1-mil polyamide mask prevents infiltration of paint during the spraying or powder-coat process. Enclosures with CMP can be baked at temperatures up to 180ºC (356ºF) for up to 30 minutes. The low-tack mask releases during baking to reveal the highly conductive fabric surface and can be easily removed.

Specifications

Fabric: Woven copper nickel fabric

Adhesive: High-tack, aggressive conductive adhesive system.

Surface Resistivity: <=0.024Ω/sq.

Resistivity through adhesive: <=10 milliohms/square inch.

Low Temperature Application: -40℉ (-40℃)

Abrasion Resistance: No change in surface resistivity after more than 1,000 wear cycles. Test method: ASTM D3884.

Shrinkage: <1% @ 180℃(356ºF) for 30 minutes. Test Method: LP-3012.

Peel Strength: 50 oz. Per inch minimum initial. Test Method: ASTM D3330.

Shielding Effectiveness: 97.4dB. Test method: Mil DTL 83528C.

Sizes

Tape Width | Tape Length | Part Number |

|---|---|---|

0.315” (8.0 mm) | 36 yard (33m) rolls | 5935-0031-4 |

0.500” (12.7 mm) | 36 yard (33m) rolls | 5935-0050-0 |

0.788“ (20.0 mm) | 36 yard (33m) rolls | 5935-0079-4 |

1.000” (25.4 mm) | 36 yard (33m) rolls | 5935-0100-7 |

1.181” (30.0 mm) | 36 yard (33m) rolls | 5935-0118-8 |

1.575” (40.0 mm) | 36 yard (33m) rolls | 5935-0157-6 |

2.000” (50.8 mm) | 36 yard (33m) rolls | 5935-0200-9 |

2.500” (63.5 mm) | 36 yard (33m) rolls | 5935-0250-4 |

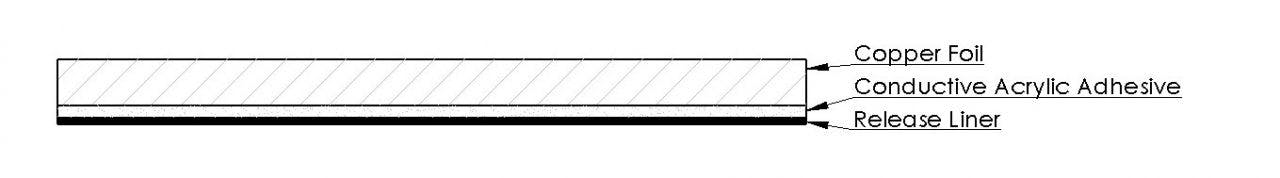

TAC-160 is a copper foil tape coated with acrylic adhesive.

It has good resistance to heat, oxidation, solvents and oils.

TAC-160 is suitable for RFI / EMI shielding applications in the electrical / electronics industry

(e.g. integrated circuit chips, cables and motors).

Material Data

Material | Thickness | Description | |

|---|---|---|---|

Base Material | Copper Foil | 0.035±0.005mm | – |

Adhesive | Conductive Acrylic Adhesive | 0.015/0.025/0.040±0.005mm | Pressure Sensitive Adhesive |

Characteristics

Unit | Typical Value | |

|---|---|---|

Overall Thickness | mm | 0.05, 0.06, 0.075 |

Tensile Strength (Copper Foil) | kg/25mm | 5 |

Elongation (Copper Foil) | % | 4 – 6 |

Surface Resistance (Copper Foil) | Ω | ≦0.05 |

Initial Tack (PSA) | kg/25mm | ≧0.65 |

Adhesion (PSA) | kg/25mm | ≧1.2 |

Temperature Resistance (PSA) | oC | 120 |

Schlegel Electronic Materials’ CFT(II) is made of using polyester rip-stop copper nickel fabric with high conductivity PSA. CFT (II) have an average shielding effectiveness over 96 dB in the frequency ranges from 20 MHz to 10 GHz. In additional to the easy-to-apply properties to fit the most EMI shielding design, it is also ideal for grounding and sealing purpose. And it is the most economical by comparing to other Schlegel EMI Conductive Tapes.

Specifications

Fabric: Nickel-Copper plated polyester ripstop fabric.

Adhesive: High-tack, conductive adhesive system.

Surface Resistivity: <= 0.066Ω/sq.

Resistivity through adhesive: <=80 milliohms/square inch.

Low Temperature Application: -40℉ (-40℃)

Abrasion Resistance: No change in surface resistivity after more than 1,000 wear cycles. Test method: ASMT D3884.

Shrinkage: <4% @ 180℃(356ºF) temperature.

Peel Strength: 50 oz. Per inch minimum initial. Test Method: ASTM D3330.

Shielding Effectiveness: 96dB Test method: Mil DTL 83528C.

Sizes

Tape Width | Tape Length | Part Number |

|---|---|---|

0.315″ (8.0 mm) | 36 yard (33m) rolls | 5923-0031-0 |

0.500″ (12.7 mm) | 36 yard (33m) rolls | 5923-0050-6 |

0.788″ (20.0 mm) | 36 yard (33m) rolls | 5923-0079-2 |

1.000″ (25.4 mm) | 36 yard (33m) rolls | 5923-0100-3 |

1.118″ (30.0 mm) | 36 yard (33m) rolls | 5923-0118-8 |

1.157″ (40.0 mm) | 36 yard (33m) rolls | 5923-0157-2 |

2.000″ (50.8 mm) | 36 yard (33m) rolls | 5923-0200-5 |

EMEI Global Network

Emei Materials Systems Limited

Unit 5, 3/F., Block A, New Trade Plaza,

6 On Ping Street, Shatin, N.T., HK

Tel :+852-2428 7878

Fax :+852-2686 8268

Email : ems@emeigroup.com / emhpsalesco1@emeigroup.com

Website : https://www.emeigroup.com/

Dongguan Emei Materials Systems Limited

No.8, QiaoxinRoad, QiaotouDongguan, Guangdong, P.R. China

Postal Code : 523525

Tel :+86-769-8334 1628/13809624596

Fax :+852-2686 8268

Email : ems@emeigroup.com / emhpsalesco1@emeigroup.com

Website : https://www.emeigroup.com/

Emei Materials Systems (Shanghai) Limited

4/F, 79 Parts, 111 Meisheng Road, F.T.Z., Pudong, Shanghai, China

Postal Code : 200131

Tel :+86-21 5868 3381

Fax :+86-21 5868 3386

SCHLEGEL ELECTRONIC MATERIALS ASIA LIMITED

Unit 5, 3/F., Block A, New Trade Plaza,

6 On Ping Street, Shatin, N.T., HK

Visit Us

Tel :+852-2686 8168

Fax :+852-2686 8268

Email : emeihk@emeigroup.com

Website : https://www.emeigroup.com/

SCHLEGEL (DONGGUAN) ELECTRONICS LIMITED

No.8A Qiaoxin Road, Qiaotou Dongguan, Guangdong, P.R. China

Visit Us

Postal Code : 523525

Tel :+86-769-8334 1628

Fax :+86-769-8334 2028

Email : emeidg@emeigroup.com

Website : https://www.emeigroup.com/

SCHLEGEL (SHANGHAI) ELECTRONICS LIMITED

4/F, 79 Parts,111 Meisheng Road, F. T. Z., Pudong, Shanghai, China

Postal Code : 200131

Tel :+86-21-5868 3383

Fax :+86-21-5868 3386

Email : emeish@emeigroup.com

Website : https://www.emeigroup.com/

TAIWAN SCHLEGEL ELECTRONICS LIMITED

No. 99, Alley 3, Lane 182,

Section 2 Wenhua Road, Banqiao District, Taiwan R.O.C

Tel :+886-2-8258 5148

Fax :+886-2-8258 5149

Email : emeitw@emeigroup.com

Website : https://www.emeigroup.com/

Schlegel Electronic Materials Inc.

1555 Jefferson Road, Rochester, NY 14623

Tel :+1 585-643-2000

Fax :+1 585-427-7216

Email : schlegelemi.na@schlegelemi.com

Website : https://www.schlegelemi.com/

Schlegel Electronic Materials Belgium bv

Schatting 73 BE-8210 Zedelgem Belgium

Tel :+32 59-560-270

Fax :+32 59-560-271

Email : schlegelbe@schlegelemi.com

Website : https://www.schlegelemi.com/

EMEI (HK) COMPONENTS LIMITED

Unit 5, 3/F., Block A, New Trade Plaza,

6 On Ping Street, Shatin, N.T., HK

Tel :+852-2686 8118

Fax :+852-2686 8128

Email : eclsales@emeigroup.com

Website : https://www.emeigroup.com/

DONGGUAN EMEI COMPONENTS LIMITED

No.8 Qiaoxin Road, Qiaotou Dongguan, Guangdong, P.R. China

Postal Code : 523525

Tel :+86-769-8334 8480

Fax :+86-769-8334 2028

Website : https://www.emeigroup.com/

BMC FAR EAST LIMITED

Unit 5, 3/F., Block A, New Trade Plaza,

6 On Ping Street, Shatin, N.T., HK

Tel :+852-2637 8822

Fax :+852-2686 8128

Email : bmcfe@emeigroup.com

Website : https://www.emeigroup.com/

BMC DONGGUAN LIMITED

No.8 Qiaoxin Road, Qiaotou Dongguan, Guangdong, P.R. China

Postal Code : 523525

Tel :+86-769-8345 2480

Fax :+86-769-8334 5656

Website : https://www.emeigroup.com/

Contact Us

Address

Unit 1, 3/F., Block A, New Trade Plaza,

6 On Ping Street, Shatin, N.T.,HK

- +852-2686 8168

- +852-2686 8268

- emeihk@emeigroup.com